|

SuZhou Volsun Electronics Technology CO.,LTD

|

| Home | About Us | Products | News | Payment | Inquiry Now | Download | Video |

|

Oil Resistant Cable Identification Sleeve Description

MSVLO series is Oil Resistant Cable Identification Sleeve, which is designed to meet the requirements of outstanding oil resistance. It is made of cross-linked environmentally friendly polyolefin bombarded by high power electron beam with electronic accelerators to meet high end markets where highly reliable cable& wire identification is required. MSVLO conforms to Classes 1 and 3 of AMS-DTL-23053/6, half-hard high molecular materials. Shrink ratios, both 2:1 and 3:1 are available. Oil Resistant Cable Identification Sleeve is widely used in aviation and spaceships, high speed rails EMU, submarine as well as other military and architecture industries.

Features

Fluid resistance at 70°C/158°F for 168h, such as JP-8 fuel oil, temperature rating 135°C /275°F

High reliability, permanent identification High temperature resistantance, rated temperature, 135°C VW-1Highly flame retardant, ROHS compliant Heat sensitive, swift recovery

Rated Temperature

Continuous operating temperature: -55°C~135°C/-67°F~275°F Min. shrink temperature: 85°C/185°F Full recovery temperature: 115°C~200°C/239°F~392°F, 8~3minutes Max. storage and transportation temperature: ≤+50°C/122°F

Standards Color code soundness: SAE-AS 81531 and MIL-STD-202F/215J Meets AMS-DTL-23053/5, compatibility: UL224

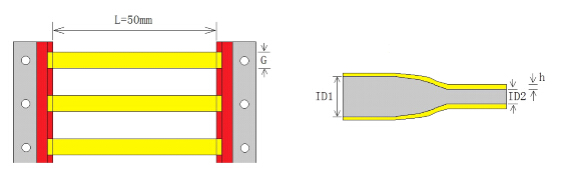

Structure

Dimensions(2:1)

Order Description

Expanded As Supplied(mm)

Recovered After Heating(mm)

Inner

Diameter ID1

Flatten

width G

Dual

Wall Thickness H

Inner

DiameterID2

Single

Wall Thickness h

MSVLO-2X-1.6/

2.00±0.20

3.7±0.3

0.48±0.10

≤0.79

0.45±0.06

MSVLO-2X-2.4/

2.79±0.20

5.0±0.3

0.48±0.10

≤1.18

0.49±0.06

MSVLO-2X-3.2/

3.64±0.23

6.3±0.4

0.48±0.10

≤1.59

0.51±0.06

MSVLO-2X-4.8/

5.26±0.25

8.9±0.4

0.49±0.10

≤2.36

0.54±0.06

MSVLO-2X-6.4/

6.92±0.28

11.5±0.4

0.50±0.10

≤3.18

0.56±0.06

MSVLO-2X-9.5/

10.2±0.32

16.7±0.5

0.51±0.11

≤4.75

0.59±0.06

MSVLO-2X-12.7/

13.5±0.36

21.8±0.6

0.52±0.11

≤6.35

0.60±0.07

MSVLO-2X-19/

20.1±0.40

32.2±0.6

0.53±0.11

≤9.53

0.62±0.07

MSVLO-2X-25/

26.7±0.45

42.5±0.7

0.55±0.12

≤12.7

0.63±0.07

MSVLO-2X-38/

39.8±0.51

63.2±0.8

0.57±0.12

≤19.1

0.64±0.07

MSVLO-2X-51/

53.0±0.56

83.9±0.9

0.58±0.13

≤25.4

0.64±0.08

MSVLO-2X-76/

79.4±0.56

125.3±1.0

0.59±0.13

≤38.1

0.64±0.09

Dimensions(3:1)

Order Description

Expanded As Supplied (mm)

Recovered After Heating (mm)

Internal

Diameter ID1

Flatten

Width G

Dual

Wall Thickness H

Inner

Diameter ID2

Single

Wall Thickness h

MSVLO-3X-1.6/

2.00±0.20

3.7±0.3

0.47±0.10

≤0.53

0.52±0.06

MSVLO-3X-2.4/

2.79±0.20

5.0±0.3

0.47±0.10

≤0.79

0.57±0.06

MSVLO-3X-3.2/

3.64±0.23

6.3±0.4

0.48±0.10

≤1.06

0.61±0.06

MSVLO-3X-4.8/

5.26±0.25

8.9±0.4

0.49±0.10

≤1.59

0.67±0.06

MSVLO-3X-6.4/

6.92±0.28

11.5±0.4

0.50±0.10

≤2.36

0.71±0.06

MSVLO-3X-9.5/

10.2±0.32

16.7±0.5

0.52±0.11

≤3.18

0.77±0.06

MSVLO-3X-12.7/

13.5±0.36

21.8±0.6

0.53±0.11

≤4.75

0.80±0.07

MSVLO-3X-19/

20.1±0.40

32.2±0.6

0.55±0.11

≤6.35

0.84±0.07

MSVLO-3X-25/

26.7±0.45

42.5±0.7

0.56±0.12

≤8.47

0.86±0.07

MSVLO-3X-38/

39.8±0.51

63.2±0.8

0.57±0.12

≤12.9

0.89±0.07

MSVLO-3X-51/

53.0±0.56

83.9±0.9

0.57±0.13

≤17.2

0.90±0.08

MSVLO-3X-76/

79.4±0.56

125.3±1.0

0.59±0.13

≤25.8

0.92±0.09

Standard Package Data

No.

Sizes

Packaging(Pcs/Reel)

Box 210

Box 146

1

Φ1.6

2500

250

2

Φ2.4

2500

250

3

Φ3.2

2000

250

4

Φ4.8

2000

250

5

Φ6.4

1500

250

6

Φ9.5

1000

250

7

Φ12.7

500

250

8

Φ19

500

250

9

Φ25

500

250

10

Φ38

250

250

11

Φ51

250

250

12

Φ76

250

250

Technical Performance

Performance

Indicators

Test Method

Typical

properties

Unit

States

Tensile Strength

Mpa

Unaged

≥10.3

ASTM G 154,MIL-DTL-23053E

ISO 37,500mm/min

175°C,168h,ISO 188

Heat aged/ After fluids/UV aged

≥6.9

Elongation at

break

%

Unaged

≥200

Heat aged/ After fluid

≥100

Secant Modulus

Mpa

Unaged

<173

ASTM D 882

Voltage

Withstand

V

Unaged / After aged

2500V, No breakdown in 60 sec.

IEC 243,ASTM G 154

175°C,168h,ISO 188

Dielectric Strength

MV/m

Before aged

≥19.7

Heat aged/ After fluid/ UV aged

≥15.8

Volume

Resistivity

Ω.cm

Unaged

≥1014

IEC 93

Dielectric

constant

-

Unaged

≤3.1

ASTM 150

Water Absorption

-

Unaged

≤0.5%

ASTM 570,23°C,24h

Bare Copper

Corrosion

-

Unaged

No corrosion

23°C,Rh 95±5%,24h

175°C,16h

Heat Shock

-

Unaged

No cracks, flowing, dripping

Wind to the specified mandrel,225°C,4h

Cold Flexibility

-

Unaged

No cracks

Wind to the specified mandrel,-55°C,1h

Flammability

-

Unaged

VW-1

IEC 60332-1-3 Ed.1.0 b:2004

Longitudinal

Change

%

Unaged

2X:-10~+1

200°C,Constant 3min

3X:-15~+5

Smoke Density

-

Unaged

-

DIN 5510-2

Toxcity Index

-

Unaged

-

BS 6853:1999

New Products

Relative Keywords

You may also be interested in:

Business Type:

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Deutsch Deutsch

|

Español Español |

Français Français |

Italiano Italiano |

Português Português |

日本の 日本の |

한국어 한국어 |

العربية العربية |

български български |

hrvatski hrvatski |

česky česky | |

Dansk Dansk |

Nederlands Nederlands |

suomi suomi |

Ελληνικά Ελληνικά |

हिन्दी हिन्दी |

norsk norsk |

Polski Polski |

Română Română |

русский русский |

Svenska Svenska |

中文 中文 |

Friendly Link: Volsun heat shrink tube | Link

Copyright © SuZhou Volsun Electronics Technology CO.,LTD All rights reserved.

Hot Products: A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z | 0~9 |

Single Wall Heat Shrink Tubing

Single Wall Heat Shrink Tubing