|

SuZhou Volsun Electronics Technology CO.,LTD

|

| Home | About Us | Products | News | Payment | Inquiry Now | Download | Video |

|

135C Heat Shrinkable Wire Identification Sleeve

Description

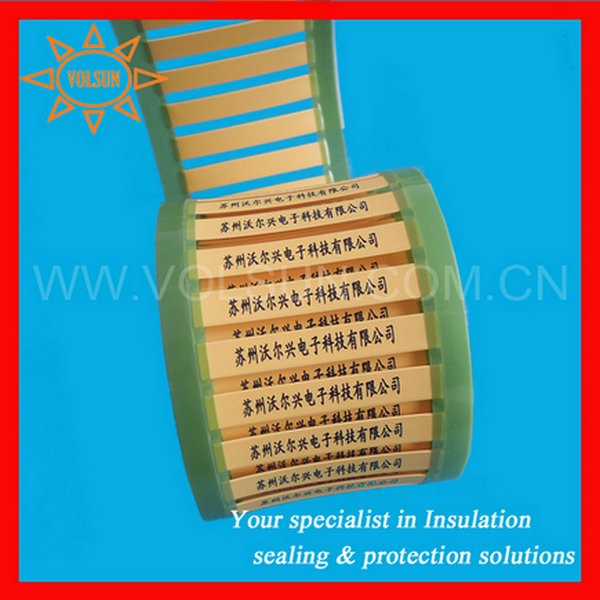

MSVLA series is the military grade cable and wire identification sleeves, which is made of cross-linked environmentally friendly polyolefin bombarded by high-power electron beam with electronic accelerators to meet requirements of high end markets where highly reliable cable& wire identification is required. It accords to Classes 1 and 3 of AMS-DTL-23053/5 half-hard high molecular materials. For this product, both 2:1 and 3:1 shrink ratio are available on your request.

Features

Military grade, lightweight, well suited for aerospace vehicles, tank, andsubmarines identification purposes High temperature resistant(temperature rating 135°C/275°F) Highly flame retardant, VW-1 RoHS compliant Highly reliable and permanent identification Thermo-sensitive, quick recovery Computer-printable, any characters and logo are easy to design

Rated Temperature

Continuous operating temperature: -55°C~135°C/-67°F~275°F Min. shrink temperature: 85°C/185°F Full recovery temperature: 115°C~200°C/239°F~392°F, 8~3minutes Max. storage and transportation temperature: ≤+50°C/122°F

Standards Meets AMS-DTL-23053/5, compatibility: UL224 Color code soundness: SAE-AS 81531 and MIL-STD-202F/215J

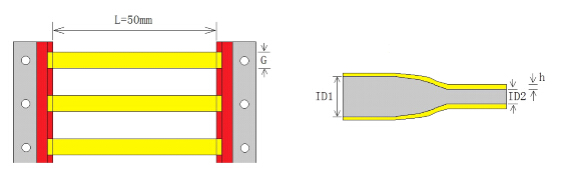

Structure

Dimensions(2:1)

Order

Description

Expanded As

Supplied(mm)

Recovered After

Heating(mm)

Inner Diameter

ID1

Flatten width G

Dual Wall

Thickness H

Inner

DiameterID2

Single Wall

Thickness h

MSVLA-2X-1.6/

2.00±0.20

3.7±0.3

0.48±0.10

≤0.79

0.45±0.06

MSVLA-2X-2.4/

2.79±0.20

5.0±0.3

0.48±0.10

≤1.18

0.49±0.06

MSVLA-2X-3.2/

3.64±0.23

6.3±0.4

0.48±0.10

≤1.59

0.51±0.06

MSVLA-2X-4.8/

5.26±0.25

8.9±0.4

0.49±0.10

≤2.36

0.54±0.06

MSVLA-2X-6.4/

6.92±0.28

11.5±0.4

0.50±0.10

≤3.18

0.56±0.06

MSVLA-2X-9.5/

10.2±0.32

16.7±0.5

0.51±0.11

≤4.75

0.59±0.06

MSVLA-2X-12.7/

13.5±0.36

21.8±0.6

0.52±0.11

≤6.35

0.60±0.07

MSVLA-2X-19/

20.1±0.40

32.2±0.6

0.53±0.11

≤9.53

0.62±0.07

MSVLA-2X-25/

26.7±0.45

42.5±0.7

0.55±0.12

≤12.7

0.63±0.07

MSVLA-2X-38/

39.8±0.51

63.2±0.8

0.57±0.12

≤19.1

0.64±0.07

MSVLA-2X-51/

53.0±0.56

83.9±0.9

0.58±0.13

≤25.4

0.64±0.08

MSVLA-2X-76/

79.4±0.56

125.3±1.0

0.59±0.13

≤38.1

0.64±0.09

Dimensions(3:1)

Order

Description

Expanded As

Supplied(mm)

Recovered After

Heating(mm)

Internal

Diameter ID1

Flatten Width G

Dual Wall Thickness

H

Inner Diameter

ID2

Single Wall

Thickness

MSVLA-3X-1.6/

2.00±0.20

3.7±0.3

0.47±0.10

≤0.53

0.52±0.06

MSVLA-3X-2.4/

2.79±0.20

5.0±0.3

0.47±0.10

≤0.79

0.57±0.06

MSVLA-3X-3.2/

3.64±0.23

6.3±0.4

0.48±0.10

≤1.06

0.61±0.06

MSVLA-3X-4.8/

5.26±0.25

8.9±0.4

0.49±0.10

≤1.59

0.67±0.06

MSVLA-3X-6.4/

6.92±0.28

11.5±0.4

0.50±0.10

≤2.36

0.71±0.06

MSVLA-3X-9.5/

10.2±0.32

16.7±0.5

0.52±0.11

≤3.18

0.77±0.06

MSVLA-3X-12.7/

13.5±0.36

21.8±0.6

0.53±0.11

≤4.75

0.80±0.07

MSVLA-3X-19/

20.1±0.40

32.2±0.6

0.55±0.11

≤6.35

0.84±0.07

MSVLA-3X-25/

26.7±0.45

42.5±0.7

0.56±0.12

≤8.47

0.86±0.07

MSVLA-3X-38/

39.8±0.51

63.2±0.8

0.57±0.12

≤12.9

0.89±0.07

MSVLA-3X-51/

53.0±0.56

83.9±0.9

0.57±0.13

≤17.2

0.90±0.08

MSVLA-3X-76/

79.4±0.56

125.3±1.0

0.59±0.13

≤25.8

0.92±0.09

Standard Package Data

No.

Sizes

Packaging(Pcs/Reel)

Box 210

Box 146

1

Φ1.6

2500

250

2

Φ2.4

2500

250

3

Φ3.2

2000

250

4

Φ4.8

2000

250

5

Φ6.4

1500

250

6

Φ9.5

1000

250

7

Φ12.7

500

250

8

Φ19

500

250

9

Φ25

500

250

10

Φ38

250

250

11

Φ51

250

250

12

Φ76

250

250

Technical Performance

Performance

Indicators

Test Method

Typical

properties

Unit

States

Tensile Strength

Mpa

Unaged

≥10.3

ASTM G 154,MIL-DTL-23053E

ISO 37,500mm/min

175°C,168h,ISO 188

Heat aged/ After fluids/UV aged

≥6.9

Elongation at

break

%

Unaged

≥200

Heat aged/ After fluid

≥100

Secant Modulus

Mpa

Unaged

<173

ASTM D 882

Voltage

Withstand

V

Unaged / After aged

2500V, No breakdown in 60 sec.

IEC 243,ASTM G 154

175°C,168h,ISO 188

Dielectric Strength

MV/m

Before aged

≥19.7

Heat aged/ After fluid/ UV aged

≥15.8

Volume

Resistivity

Ω.cm

Unaged

≥1014

IEC 93

Dielectric

constant

-

Unaged

≤3.1

ASTM 150

Water Absorption

-

Unaged

≤0.5%

ASTM 570,23°C,24h

Bare Copper

Corrosion

-

Unaged

No corrosion

23°C,Rh 95±5%,24h

175°C,16h

Heat Shock

-

Unaged

No cracks, flowing, dripping

Wind to the specified mandrel,225°C,4h

Cold Flexibility

-

Unaged

No cracks

Wind to the specified mandrel,-55°C,1h

Flammability

-

Unaged

VW-1

IEC 60332-1-3 Ed.1.0 b:2004

Longitudinal

Change

%

Unaged

2X:-10~+1

200°C,Constant 3min

3X:-15~+5

Smoke Density

-

Unaged

-

DIN 5510-2

Toxcity Index

-

Unaged

-

BS 6853:1999

New Products

Relative Keywords

You may also be interested in:

Business Type:

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Deutsch Deutsch

|

Español Español |

Français Français |

Italiano Italiano |

Português Português |

日本の 日本の |

한국어 한국어 |

العربية العربية |

български български |

hrvatski hrvatski |

česky česky | |

Dansk Dansk |

Nederlands Nederlands |

suomi suomi |

Ελληνικά Ελληνικά |

हिन्दी हिन्दी |

norsk norsk |

Polski Polski |

Română Română |

русский русский |

Svenska Svenska |

中文 中文 |

Friendly Link: Volsun heat shrink tube | Link

Copyright © SuZhou Volsun Electronics Technology CO.,LTD All rights reserved.

Hot Products: A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z | 0~9 |

Single Wall Heat Shrink Tubing

Single Wall Heat Shrink Tubing