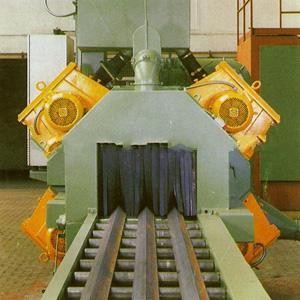

usage:

H beam Shot blasting machinefor shot blasting the surface rust and painted with a protective coat of processing technology. After pre-treatment of steel products can improve the mechanical and corrosion-resistant metal components ability of anti-fatigue properties of steel, extending its life; but also can optimize the production process of steel surface, and is conducive to cutting machine CNC cutting and precision blanking . In addition, pre-processing of steel as a result of comparing the shape of the rules in favor of mechanical and automated spray paint rust, so the use of steel pre-treatment can enhance the efficiency of clean-up, clean-up operations to reduce labor intensity and the pollution of the environment. In recent years, as a result of the use of PLC control, automation equipment, greater emphasis has been improved.

Technical data:

Work-piece:

Length: 6000-12, 000mm

WxH: 500x800, 500x1200, 600x1000, 600x1400, 800x1400, 800x1600mm

Transporting roller:

Transporting speed m/min: 0.5-6

Working speed m/min: 0.5-1.5

Power KW: 2 x 2.2

Blasting wheel:

Model: XQH300

Quantity: 4 or 8

Power KW: 4x 11 or 8 x 11

Blasting capacity kg/min: 4x200 or 8x200

Bucket elevator:

Elevating capacity t/h: 50 or 100

Separator:

Separating capacity t/h: 50 or 100

Screw conveyor:

Quantity: 2

Conveying capacity t/h: 50 or 100

Pill-feeding Quantity: 4 or 8

Dusting collector:

Model: HR-12 or HR-16

Dusting: 99%

- through type shot blasting machine

- Hook type shot blasting machine

- hanger type shot blasting machine

- catenary type shot blasting machine

- Roller Through type shot blasting machine

- Through shot blasting machine

- shot blasting machine

- Catenary shot blasting machine

- Pass through shot blasting machine

- Q32 series of shot blasting machine

- Deck shot blasting machine

- Overhead shot blasting machine

- Hook shot blasting machine

- roller through shot blasting machine

- road shot blasting machine

-1346999902-0.jpg)

-1347001471-0.jpg)

Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano Português

Português 日本の

日本の 한국어

한국어 العربية

العربية български

български hrvatski

hrvatski česky

česky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικά

Ελληνικά हिन्दी

हिन्दी norsk

norsk Polski

Polski Română

Română русский

русский Svenska

Svenska 中文

中文