|

Dongguan Evertop Printing Supplies Limited

|

| Home | About Us | News & FAQ | Products | Trade With Us | Inquiry Now |

|

Product Description

Low price 402 Spun polyester sewing thread

High tenacity SP thread for leather

1.Description of sewing thread:

Basics of thread construction

All conventional sewing threads begin their production cycle as simple yarns. These basic yarns are produced by twisting together relatively short fibres or fine continuous filaments.

Twist – The ‘twist’ of a thread refers to the number of turns per unit length required to hold the fibres / plies together to give the yarn / thread substance the required strength and flexibility. A thread with an excessive twist is also likely to give trouble while sewing due to ‘twist liveliness’, which can cause snarling, loops, knots and possible spillage that prohibit stitch formation.

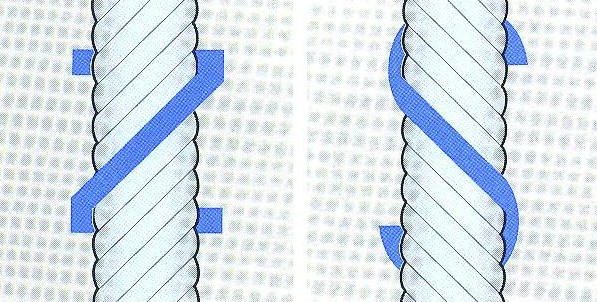

Twist direction – Direction of twist is identified as ‘S’ for left twist and ‘Z’ for right twist. Most single needle lock stitch and other machines are designed for ‘Z’ twist threads. ‘S’ twist thread untwists during stitch formation. Basics of thread construction

All conventional sewing threads begin their production cycle as simple yarns. These basic yarns are produced by twisting together relatively short fibres or fine continuous filaments.

Twist – The ‘twist’ of a thread refers to the number of turns per unit length required to hold the fibres / plies together to give the yarn / thread substance the required strength and flexibility. A thread with an excessive twist is also likely to give trouble while sewing due to ‘twist liveliness’, which can cause snarling, loops, knots and possible spillage that prohibit stitch formation.

Twist direction – Direction of twist is identified as ‘S’ for left twist and ‘Z’ for right twist. Most single needle lock stitch and other machines are designed for ‘Z’ twist threads. ‘S’ twist thread untwists during stitch formation.

Direction of twist does not affect the strength of the thread, but it can seriously impair its performance when it is used on a machine for which it is not suited.

Ply and cord – Yarns with many components are twisted together to form ply thread. Most commonly used are 2, 3 or 4 ply threads. Threads are twisted together to give corded thread. Most commonly used are 4, 6 or 9 cord threads.

Size – The overall thickness of the final thread is referred to as ‘Grist’, ‘Ticket Number’, ‘Tex’ or ‘Count’. Thread should be as fine as possible depending on the required strength of seam. Generally, thicker threads have greater strength, given the same fibre content and yarn structure. Finer threads tend to blend into the fabric surface and are less subject to abrasion than seams with heavier threads. Finer threads perform better with finer needles and produce less fabric distortion than heavier needles.

Direction of twist does not affect the strength of the thread, but it can seriously impair its performance when it is used on a machine for which it is not suited. Ply and cord – Yarns with many components are twisted together to form ply thread. Most commonly used are 2, 3 or 4 ply threads. Threads are twisted together to give corded thread. Most commonly used are 4, 6 or 9 cord threads.

Size – The overall thickness of the final thread is referred to as ‘Grist’, ‘Ticket Number’, ‘Tex’ or ‘Count’. Thread should be as fine as possible depending on the required strength of seam. Generally, thicker threads have greater strength, given the same fibre content and yarn structure. Finer threads tend to blend into the fabric surface and are less subject to abrasion than seams with heavier threads. Finer threads perform better with finer needles and produce less fabric distortion than heavier needles.

Product attribute & Spec.

2.1 Material :100% Polyester

2.2 Needle & strenght for your refer:

Outstanding Features · No breakages in high-speed sewing · Consistent stitch formation · No skipped stitches · Evenness, to prevent changes in tension during sewing · A high level of abrasion resistance · Sufficient surface smoothness, to pass easily through the machine guides .About the color : 1)We have more then 400 hundres color for your refer 2)We can dyed any color as your requirement

6.Spun polyester thread Application : Jeans , bookbonded ,hand bag,etc.

Packaging & Shipping

7.Spun polyester thread packing show:

8.Carton boxes & Packing:

PS: Didfferent packing different carton boxes size: 1) Yarn Count: 12/3, 12/4, 12/5, 20/2, 20/3, 20/4, 20/6, 20/9, 30/2, 30/3, 40/2, 40/3, 42/2, 50/2, 50/3, 60/2, 60/3 etc; 2) Net Weight: 100g, 200g, 250g, 500g, 1kg, 1.25kg, 1.667kg, 2kg/cone etc; 3) Length: 2000m, 3000m, 5000m, 3000Y, 5000Y, etc. 1. Carton size for 100g:45.5*29.5*24.5CM=0.004M3 (80 cones /carton) 2. Carton size for 190g:36*36*23CM=0.032M3 (50 cones /carton) 3.Carton size for 1250g:61.5*31.5*37CM=0.072M3 (16cones/carton) 4.Carton size for 1000g:56*42*36.2CM=0.09M3 (24cones/carton)

Our Points Good service: Fast leading time

Is nothing !

New Products

Relative Keywords

You may also be interested in:

Business Type:

| |||||||||||||||||||||||||||||||||||||||

Deutsch Deutsch

|

Español Español |

Français Français |

Italiano Italiano |

Português Português |

日本の 日本の |

한국어 한국어 |

العربية العربية |

български български |

hrvatski hrvatski |

česky česky | |

Dansk Dansk |

Nederlands Nederlands |

suomi suomi |

Ελληνικά Ελληνικά |

हिन्दी हिन्दी |

norsk norsk |

Polski Polski |

Română Română |

русский русский |

Svenska Svenska |

中文 中文 |

Friendly Link: Link

Copyright © Dongguan Evertop Printing Supplies Limited All rights reserved.

Hot Products: A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z | 0~9 |

Textile Material

Textile Material

-ciss-for-hp/CISS-for-HP950-951-1366616109-0.jpg)