PP Woven Bag Making Plant

Products description:

PP woven bag /sacks whole plant project

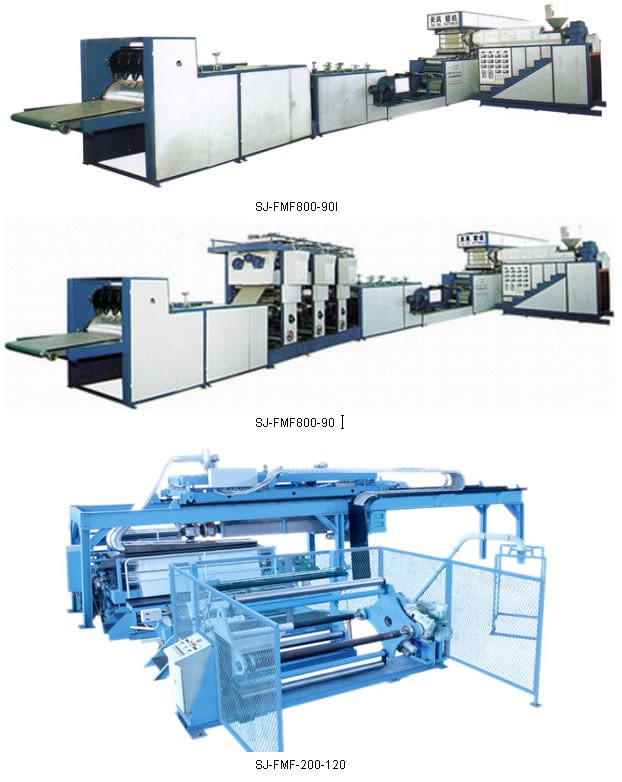

These machines use polypropylene (PP) or PE as raw material to produce plastic bags (PP woven bags), which are suitable for packing powder or solid materials such as fertilizer, cement, grain, salt, sugar, laundry soap powder and they can also be used for packing cotton, tobacco and vegetable etc.

1) PP yarn or PP tape width:2.0 mm , 2.5 mm width

2) PP yarn or PP tape density: 540 dennier or above

3) Annual production capactiy of plasitic woven sacks: 5 Million PCS or above, Minimum capacity required: 5 Million

4)Lamination: Laminating width:300mm to 2800 mm , laminated with PP/PE plastic film, or laminated with paper.

5)Printing colors: no printing, or printing more than 8 colors available, printing length150 mm to 1500 mm .

6)Cutting and sewing: manual operated, or fully automatic,

7)Baling press: mechanical or hydraulic pressing,

8)Adapt to recycled PP/PE material, recycled material up to 30% or more. Or choosing high speed pp tape extrusion line, use new PP/PE raw material only.

9)Recycling granulator and crushing machine for recycling the waste fabric during production.

10) Facility equipments, accessories, spare parts available accordingly.

These machines use polypropylene (PP) or PE as raw material to produce plastic bags (PP woven bags), which are suitable for packing powder or solid materials such as fertilizer, cement, grain, salt, sugar, laundry soap powder and they can also be used for packing cotton, tobacco and vegetable etc.

1) PP yarn or PP tape width:

2) PP yarn or PP tape density: 540 dennier or above

3) Annual production capactiy of plasitic woven sacks: 5 Million PCS or above, Minimum capacity required: 5 Million

4)Lamination: Laminating width:

5)Printing colors: no printing, or printing more than 8 colors available, printing length

6)Cutting and sewing: manual operated, or fully automatic,

7)Baling press: mechanical or hydraulic pressing,

8)Adapt to recycled PP/PE material, recycled material up to 30% or more. Or choosing high speed pp tape extrusion line, use new PP/PE raw material only.

9)Recycling granulator and crushing machine for recycling the waste fabric during production.

10) Facility equipments, accessories, spare parts available accordingly.

New Products

Inverter Winder

View Detail

Plastic rope making machine

View Detail

Flexographic Printing Machine

View Detail

6 Color Gravure Printing Machine

View Detail-Printing-Machine-1328244750-0.jpg)

Bags (offset) Printing Machine

View Detail

PP Woven Bag Making Plant

View Detail

Jumbo Bag Making Machine

View Detail

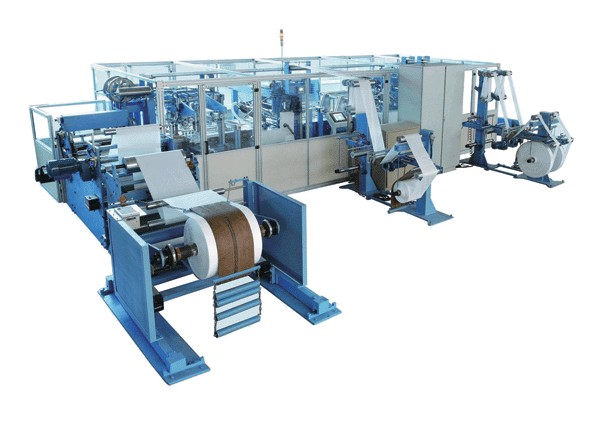

Cement Bag Production Line

View Detail

PP Block Bottom Valve Bag Machines

View Detail

SJ-FS5.5 Series PP Flat Tape Extruder

View DetailRelative Keywords

You may also be interested in:

Business Type: