| MODEL: | MSVLU |

| SIZE: | 1.6mm to 76mm |

| PACKAGE: | 250PCS/BOX |

Cable Use Identification Marker Sleeve

Description

Cable use identification marker sleeve is halogen free, environmentally friendly, heat shrinkable identification sleeves. It is made of cross-linked environmentally friendly polyolefin bombarded by high power electron beam with electronic accelerators to meet high end markets where highly reliable, economical and environmentally friendly cable& wire identification is required. It accords to the requirements of UL224, CAN/CSA C22.2. Shrink ratios, both 2:1 and 3:1 are available. See the below tables.

Features

Halogen free, ideally used for electronic or electrical circuits,

communications, architecturalindustries

Temp. Resistance: 125°C

Highly flame retardant, VW-1

ROHS compliant and meet SONY SS-00259

High reliability, permanent identification

Heat sensitive, shrinking quickly

Computerized lettering or fonts at your disposal.

Standard Color: yellow, white

Rated Temperature

Continuous operating temperature: -55°C~125°C/-67°F~257°F

Min. shrink temperature: 85°C/185°F

Full recovery temperature: 115°C~200°C/239°F~392°F, 8~3minutes

Max. storage and transportation temperature: ≤50°C/122°F

Standards

Material Standard: UL224, CAN/CSA C22.2

Color Code Soundness: SAE-AS 81531and MIL-STD-202F/215J

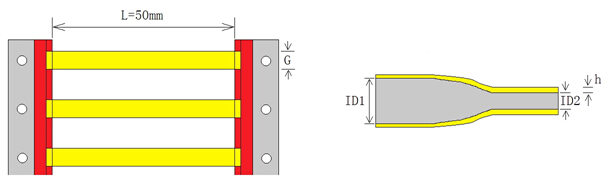

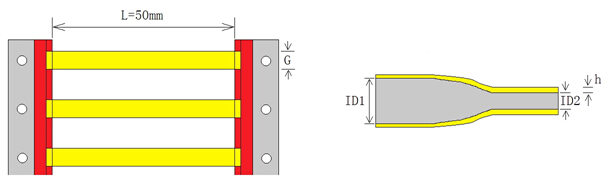

Structure

Dimensions(2:1)

|

Order Description

|

Expanded As Supplied (mm)

|

Recovered After Heating (mm)

|

|

Inner

Diameter ID1

|

Flatten

width G

|

Dual

Wall Thickness H

|

Inner

DiameterID2

|

Single

Wall Thickness h

|

|

MSVLU-2X-1.6/

|

2.00±0.20

|

3.7±0.3

|

0.48±0.10

|

≤0.79

|

0.45±0.06

|

|

MSVLU-2X-2.4/

|

2.79±0.20

|

5.0±0.3

|

0.48±0.10

|

≤1.18

|

0.49±0.06

|

|

MSVLU-2X-3.2/

|

3.64±0.23

|

6.3±0.4

|

0.48±0.10

|

≤1.59

|

0.51±0.06

|

|

MSVLU-2X-4.8/

|

5.26±0.25

|

8.9±0.4

|

0.49±0.10

|

≤2.36

|

0.54±0.06

|

|

MSVLU-2X-6.4/

|

6.92±0.28

|

11.5±0.4

|

0.50±0.10

|

≤3.18

|

0.56±0.06

|

|

MSVLU-2X-9.5/

|

10.2±0.32

|

16.7±0.5

|

0.51±0.11

|

≤4.75

|

0.59±0.06

|

|

MSVLU-2X-12.7/

|

13.5±0.36

|

21.8±0.6

|

0.52±0.11

|

≤6.35

|

0.60±0.07

|

|

MSVLU-2X-19/

|

20.1±0.40

|

32.2±0.6

|

0.53±0.11

|

≤9.53

|

0.62±0.07

|

|

MSVLU-2X-25/

|

26.7±0.45

|

42.5±0.7

|

0.55±0.12

|

≤12.7

|

0.63±0.07

|

|

MSVLU-2X-38/

|

39.8±0.51

|

63.2±0.8

|

0.57±0.12

|

≤19.1

|

0.64±0.07

|

|

MSVLU-2X-51/

|

53.0±0.56

|

83.9±0.9

|

0.58±0.13

|

≤25.4

|

0.64±0.08

|

|

MSVLU-2X-76/

|

79.4±0.56

|

125.3±1.0

|

0.59±0.13

|

≤38.1

|

0.64±0.09

|

Dimensions(3:1)

|

Order Description

|

Expanded As Supplied (mm)

|

Recovered After Heating (mm)

|

|

Internal

Diameter ID1

|

Flatten

Width G

|

Dual

Wall Thickness H

|

Inner

Diameter ID2

|

Single

Wall Thickness h

|

|

MSVLU-3X-1.6/

|

2.00±0.20

|

3.7±0.3

|

0.47±0.10

|

≤0.53

|

0.52±0.06

|

|

MSVLU-3X-2.4/

|

2.79±0.20

|

5.0±0.3

|

0.47±0.10

|

≤0.79

|

0.57±0.06

|

|

MSVLU-3X-3.2/

|

3.64±0.23

|

6.3±0.4

|

0.48±0.10

|

≤1.06

|

0.61±0.06

|

|

MSVLU-3X-4.8/

|

5.26±0.25

|

8.9±0.4

|

0.49±0.10

|

≤1.59

|

0.67±0.06

|

|

MSVLU-3X-6.4/

|

6.92±0.28

|

11.5±0.4

|

0.50±0.10

|

≤2.36

|

0.71±0.06

|

|

MSVLU-3X-9.5/

|

10.2±0.32

|

16.7±0.5

|

0.52±0.11

|

≤3.18

|

0.77±0.06

|

|

MSVLU-3X-12.7/

|

13.5±0.36

|

21.8±0.6

|

0.53±0.11

|

≤4.75

|

0.80±0.07

|

|

MSVLU-3X-19/

|

20.1±0.40

|

32.2±0.6

|

0.55±0.11

|

≤6.35

|

0.84±0.07

|

|

MSVLU-3X-25/

|

26.7±0.45

|

42.5±0.7

|

0.56±0.12

|

≤8.47

|

0.86±0.07

|

|

MSVLU-3X-38/

|

39.8±0.51

|

63.2±0.8

|

0.57±0.12

|

≤12.9

|

0.89±0.07

|

|

MSVLU-3X-51/

|

53.0±0.56

|

83.9±0.9

|

0.57±0.13

|

≤17.2

|

0.90±

|

Single Wall Heat Shrink Tubing

Single Wall Heat Shrink Tubing

Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano Português

Português 日本の

日本の 한국어

한국어 العربية

العربية български

български hrvatski

hrvatski česky

česky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικά

Ελληνικά हिन्दी

हिन्दी norsk

norsk Polski

Polski Română

Română русский

русский Svenska

Svenska 中文

中文