|

Detailed Product Description

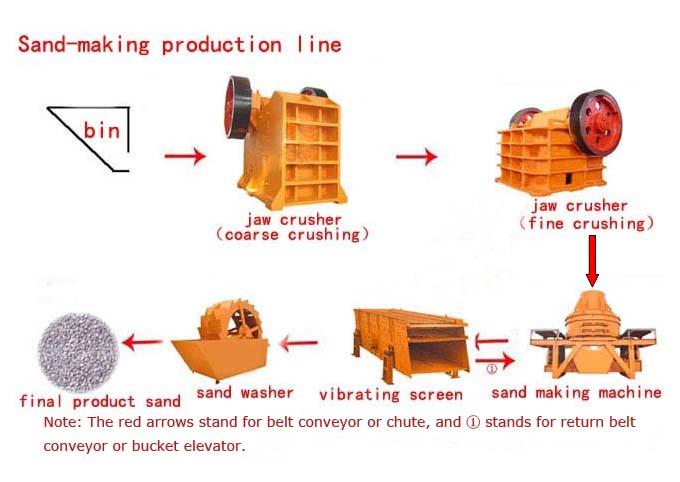

Brief introduction of Stone/Sand Production Line:

The Stone Production Line is made up of Vibrating Feeder, Jaw Crusher, Impact Crusher, Cone Crusher, Vibrating Screen, Belt Conveyor, Central Electric Panel etc.

We provide customers not only Stone Making Machinery with wide choices, reasonable process, reliable quality and lower cost but also selecting system of Stone Crushing with whole design, processing plant and successful project of the Stone Making Process. The materials crushed in the stone system totally satisfy the technical requests of overall sizes for the surface of highway, water and electricity construction, concrete mixing, etc.

All the products have passed the quality system certification of ISO9001.

Guarantee terms: All the machines excluding spare parts are guaranteed one year. Spare parts can be replaced on favorably for the buyer.

We take 150-180t/h Stone Production Line like below for example to explain our products by details:

Brief introduction of Equipment:

1. Vibrating Feeder:

(1) Description of Vibrating Feeder

The Vibrating Feeder is a kind of linear direction feeding equipment . Vibrating Feeder makes a feature of smooth vibrating, reliable in operation, long service life and suitable for feeding. Vibrating Feeders are widely used in mining, building-material, silicate and chemical industry in the crushing and screening plants.

(2) Specifications of Vibrating Feeder

|

Models

|

Max. Feed Size

(mm)

|

Capacity

(t/h)

|

Electric Motor Power

(KW)

|

Weight

(kg)

|

Overall Dimensions

(L*W*H)

|

|

GZD1100*4200

|

580

|

200~430

|

15

|

4170

|

4400*2050*1660

|

2. Jaw Crusher

3. Impact Crusher

4. Vibrating Screen

5. Belt Conveyer

(1) Introduction of Belt Conveyer

The conveyers consist of standard parts, which are advanced and simple in structure, easy to maintain. Our vibrating equipment is adaptable for stationary and mobile crushing plants. They are widely used in mining, metallurgical and coal industry to transfer sandy or lump material, or packaged material. According to different transferring equipment, the transfer system can be one independently or multi-conveyers or combined with other transfer equipments. The belt conveyer can be installed horizontally or aslope to meet the needs of different transfer lines.

The belt conveyers produced by SJLC can be operated in the circumstance temperature range from -20 to +40. The temperature of transferred material by this belt conveyer should be lower than 50.

(2) Specifications of Belt Conveyer

|

belt width

(mm)

|

belt length (m) /power (Kw)

|

belt speed(m/s)

|

Capacity

(t/h)

|

|

500

|

Below 12/3

|

12~20/4~5.5

|

20~30/ 5.5~7.5

|

1.3~1.6

|

45~100

|

|

650

|

below12/4

|

12~20/5.5

|

20~30/7.5~11

|

1.3~1.6

|

70~120

|

|

800

|

below10/4

|

10~15/5.5

|

15~25/7.5~15

|

1.3~1.6

|

120~180

|

|

1000

|

below10/5.5

|

10~20/7.5~11

|

20~25/11~12

|

1.3~2.0

|

160~250

|

6. Electric Panel

The electric motor is controlled synthetically by the electric equipment. The main purpose of the electric panel is to make the equipment steadier and safer when starting.

150~180t/h Stone Production Line Configure List

|

Equipment

|

Model

|

Quantity

(pcs)

|

Unit Power

(kw)

|

Unit Weight

(t)

|

|

Hopper

|

LC3000*4000

|

1

|

~~~

|

~~~

|

|

Vibrating feeder

|

GZD1100*4200

|

1

|

15

|

4.17

|

|

Jaw Crusher

|

PE750*1060

|

1

|

110

|

28

|

|

Impact Crusher

|

PF1315

|

1

|

200

|

19

|

|

Vibrating Screen

|

4YZS2160

|

1

|

37

|

10

|

|

Belt Conbeyor

|

B1000*16m

|

1

|

7.5

|

~~~

|

B1000*24m

|

1

|

11

|

~~~

|

B800*25m

|

1

|

7.5

|

~~~

|

B650*15m

|

4

|

5.5

|

~~~

|

|

Electric Switch box

|

~~~

|

2

|

~~~

|

~~~

|

Note:

We can also supply with other Capacity according to clients' concrete requirement. Call me, let's do business!

|