|

Detailed Product Description

Product Description

Descriptions:

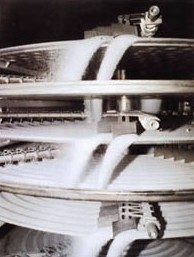

PLG series continuous plate dryer is a kind of high efficiency conducting and continuous drying equipment. Its unique structure and operating principle provide advantages of high heat efficiency, low energy consumption, less occupying area, simple configuration, easy operation and control as well as good operating environment etc. It is widely used in drying process in the fields of chemical, pharmaceuticals, agricultural chemicals, foodstuff, fodder, process of agricultural and by-products etc., and is well received by various industries. Now there are three big categories, normal pressure, closed and vacuum styles and four specifications of 1200, 1500, 2200 and 2500; And three kinds of constructions A (carbon steel), B(stainless steel for contact parts) and C (on the basis of B to add stainless steel for steam pipes, main shaft and support, and stainless steel linings for cylinder body and top cover). With a drying area of 4 to 180 square meters, now we have hundreds of models of series products and various kinds of auxiliary devices available to meet requirements of various products.

Principle:

Wet materials are fed continuously to the top drying layer in the dryer. They will be turned and stirred continuously by harrows when the harrow's arm rotates, the material flows through the surface of the drying plate along the exponential helical line. On the small drying plate the material will be moved to its exterior edge and drop down to the exterior edge of the large drying plate underneath, and will then be moved inward and drop down from its central hole to the small drying plate on the next layer. Both small and large drying plates are arranged alternately so as materials can go through the whole dryer continuously. The heating media, which could be saturated steam, hot water or thermal oil will be LED into hollow drying plates from one end to other end of the dryer. The dried product will drop from the last layer of the drying plate to the bottom layer of the smell body, and will be moved by harrows to the discharge port. The moisture exhausts from materials and will be removed from the moist discharge port on the top cover, or sucked out by the vacuum pump on the top cover for vacuum-type plate dryer. The dried product discharged from the bottom layer can be packed directly. The drying capability can be raised up if equipped with supplementary devices such as finned heater, condenser for solvent recovery, bag dust filter, return and mix mechanism for dried materials and suction fan etc. Solvent in those paste state and heat sensitive materials can be easily recovered, and thermal decomposition and reaction can be also carried out.

Features: /continuous plate dryer

(1). Easy control, wide application

(2). Easy and simple operation

(3). Low energy consumption

(4). Good operation environment, solvent can be recovered and powder discharge meet the requirements of exhaust.

(5). Easy installation and small occupying area.

|

Model

|

50

|

100

|

150

|

200

|

300

|

500

|

1000

|

|

Evaporated amount(kg/h)

|

50

|

100

|

150

|

200

|

300

|

500

|

1000

|

|

d(mm)ΦxH

|

1200x8900

|

1800x11500

|

2200x13500

|

2400x14800

|

2800x15400

|

3400x18800

|

4600x22500

|

|

Power(KW)

|

8.5

|

14

|

22

|

24

|

30

|

40

|

82

|

|

Inlet air temperature(°C)

|

300-350

|

|

Water content(%)

|

<5(0.5)

|

|

Yield(%)

|

>97

|

|

Evaporation and Electricity(Mpa+KW)

|

0.5+54

|

0.6+90

|

0.6+108

|

Temperature is below 200°C,calculating in accordance with pratical situation

|

|

Furnace(Kcal/h)

|

150000

|

300000

|

300000

|

400000

|

600000

|

1000000

|

1500000

|

|